|

We keep bees.

And all the work that goes into keeping them going. Like the electric fence you see in the picture. That works as a Bear deterrent. And yes we have a bear or two around right now. A bear ripped apart and helped itself to a hive we had on another part of our property. So this one gets the royal treatment. Complete with solar charged battery backed up electric fence. A mere 12 kilovolts. That should make the next hungry bear wake up a little.

1 Comment

A long time ago I played the French Horn. You will see them in the latter part of this video. I have played these parts and I enjoyed them immensely back then.

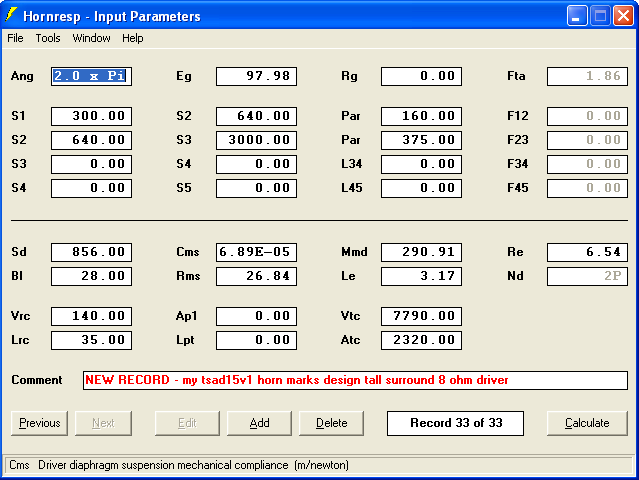

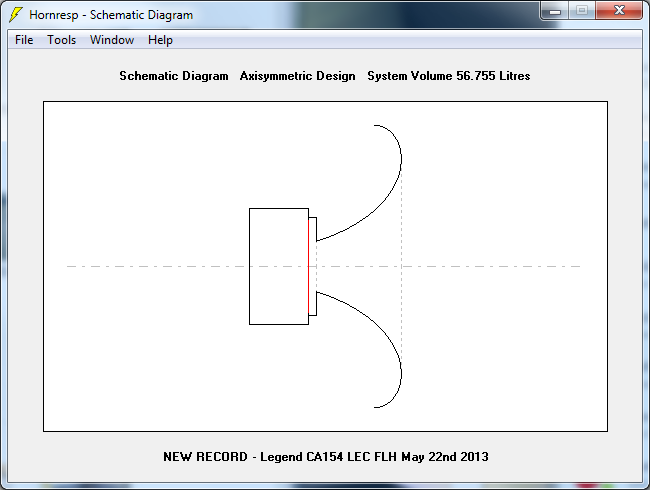

I take great pleasure in sharing this video. I have loved classical music from childhood before I knew any names of even one piece. I found the types of classical music I liked out of sheer interest and dogged determination. I have learned quite a bit, and have quite a groomed collection of music. There are many people out there who are the same. Everytime I showcase speakers that I have built I find something that really blows away people from my collection. I wish more people would have this type of a sharing spirit with their talents. The piece of music played is Beethoven's 9th, the Ode to Joy. And joyous it is. Just watch the kids in the video.  I get asked that question fairly often. Will I be making a line of speakers for the public? The offerings from Funk Audio are my design work. The models 8.2 and the 6.1 as well as the original design concept for the plate amps. I contributed to refining the TSAD Driver in terms ease of manufacturing and greatly improving the driver motors cooling. I also sent this design to Nathan in 2012: And this is what Nathan came up with: http://www.funkaudio.ca/uploads/3/7/3/2/37325201/778410_orig.jpg A nicely designed Horn Subwoofer that resembles the Orbit shifter from JTR. http://jtrspeakers.com/portable/orbit-shifter/ And it should. Becasue that was the design goal in the first place! So Yes I have designed conventional speakers. A little more unconventional: The bass section of the Volti Audio Vittora is my design work: http://voltiaudio.com/vittora/ https://web.archive.org/web/20140110022132/http://www.voltiaudio.com/newsletter/NL6.shtml Scroll down to a New Small Horn. I have also advised on the newest model 29 soon to be released from Morrison Audio. One of the few successful omni speakers that are available. We took a great tight sounding speaker and did some more work on the upper bass lower midrange. Don is an awesome designer in his own right. I just made a few suggestions. http://www.morrisonaudio.com/ Newest member of the club is Unity Audio : http://www.unityaudio.ca/ Omer has been working with some interesting wideband designs. We have come up with a floorstander that should be a very interesting departure from the sound you normally relate to a small wideband driver. One with low end. And a punchier midbass to. That should be released fairly soon. So what do I come up with for my own line? Well I can give you a bit of information on the latest offering from K-Audio. Our first offering will be a rather unique one. It's a Concentric Horn. Designed for installed home theater applications. Very high efficiency. Enormous detail put into even coverage of the room across the whole frequency range. And efficiency akin to that of a Klipsch horn speaker. As I do not like the sound of most compression drivers I have opted for a very high efficiency low distortion planar. It's coupled to a purpose built radiation pattern matched horn. Matched in the sense that the bass and midbass sound dispersion pattern will match closely with that of the midrange and high frequency as much as is possible. This kind of performance cannot be attained with a conical or straight sided horn in the midbass upwards. http://www.funkaudio.ca/blog/new-horn-loaded-main-speaker-the-122hp This speaker setup in the link above is basically a midbass or kick horn with a planar mid tweeter and a simple waveguide. Awesome for PA use! I have measured this waveguide and found it to be pretty bad at creating an even coverage verses frequency spread. It beams. This waveguide does not have the depth to properly produce a acoustical loading for the lower end of the planars reproduction. It also lacks the proper aspect ratio to support horn loading in the higher frequency range. So you have basically a midband peak in it's horn loading. I guess that's good because a straight sided horn that is supposed to cover from bass to lower midrange will also have serious beaming peaks and valleys due to it's inherent internal reflections. Parallel sides in a horn that is supposed to operate above the midbass (80 to 120 hertz region) is not a very good design path to follow. I designed a very similar dual twelve kick here: http://www.hometheatershack.com/forums/ported-subwoofer-build-projects/66454-horn-sub-input-please-build-progress-2.html#post602378 And Andy's awesome folding work: http://www.hometheatershack.com/forums/ported-subwoofer-build-projects/66454-horn-sub-input-please-build-progress-4.html#post649341 Andy Lowe is the craftsman that created the fold and the box design. This speaker is designed specifically to fill in the region in between a horn loaded low frequency subwoofer and a main set of loudspeakers. It allows maximum efficiency in the midbass region. So basically a kick drum type of a horn. Not designed in any way to be a midrange horn. So having designed and studied many types of speakers for almost the past thirty years I have come up with a few ideas! So what can a speaker designer do? Do it right! We want a pretty much spherical wavefront if we are going to have an even coverage pattern in room. Vertical and horizontal coverage. There are only a few horn types that will do that. The one I have chosen is the best. In the square profile it can still produce an almost spherical wavefront. This makes building it easier, and smaller. It is also one of the shortest types of horns for the low frequency cutoff produced. I'm pretty good at working with physics, but I can only work with them not against them! Here is a teaser of the beginning. There will be a series of YouTube videos on this loudspeaker soon enough.

The frequency range covered is a solid 70 hertz to over 20 kilohertz. Just like the Klipsch Horn. Size is approximately one meter or 3 feet square with a depth of 700 mm or 24 inches. And like the Klipsch horn this speaker will have a baseline efficiency of 105db/watt. It will actually be a little higher in room. Can you say dynamic? And lower midband distortion than the Klipsch horns to! The current design is for in wall applications and will be steerable and then fixed upon proper location. There is an MTM version that is planned. As one of my friend in the industry has said. That version will be a force of Nature all on it's own. Imagine midbass and midrange in the 108db/watt or better. It could be driven from your phone! Pricing.... $7000 a pair delivered. Limited production per year. And there are two sets that are spoken for already. One of them is the MTM version! This past Saturday April 9th I was privileged to attend the seventh annual DIY Audio Ottawa meeting. We had a blast. Listened to some great sounding audio systems designed and created by some very intelligent and thorough fellows. All the work I do in this field of endeavor is to listen to music. And we certainly had time to do this. It was great. From some mini monitors that are just simply the state of the art to a large system designed by Wayne Parham. A different sound, yet very pleasant to hear. I'm glad I could be a part of it. I came with the prototype back loaded horns. A very much improved version of those is going to be around very shortly. Some pics of the day are below: The last hiccup is done and over with.

Wow. The things I have learned over the past few days. Back up and running.

On February 1st this year I thought I transfered my domain registration to another company. Turns out that I made a simple error that caused my website to be down for two days. Thanks to some kind gentlemen especially Sandy who is a patient fellow and walked me through the mistakes that I made. One thing I have learned is to follow up on emails from web providers! I started out in this business doing custom enclosures and basic loudspeaker engineering.

It has been a part of my work for almost 30 years now. And a part that I thoroughly enjoy. This double set of enclosures has been chronicled here: https://www.youtube.com/channel/UCjhL86Eih-SnTPGByh9RfKw I put up different videos on my channel. And slowly they are getting a little better. There is a huge following ( 10 people at the moment ) ! If you have an idea for something that is a little different. Or quite complicated I am your man. The equipment and capabilities of my shop are second to none. And there is a bald guy in there from time to time that can perform modest wood working miracles to. There's a couple of things that never seem to coalesce in the life of an independant audio designer. I have time to spend designing and engineering, or I am swamped and have money but no time.

Being an independant means I answer to my clients. Not a corporate agenda on squeezing blood from tired old stones. Being independent means that I can both design to spec and design to the very hairy edge of what is possible to reproduce. And happily I have a build house that is more than willing to take on a challenge. Being independent also means that I have to fund my R&D. That is what holds back some of the best stuff that I have done design work on. I'm at a stage right now where I have lot's of time and the other part is in short supply. Sitting on four driver designs that are both wanted by the public and pushing the envelope of what is currently available. I have a shallow 8 and a shallow 6.5 that are very high performance but I do not have the funds to push through the development. There is a small form factor tweeter that is almost ready for production and a subwoofer that is ready for production. There are a few perennial designs that can be produced that would provide such funding. So either jump in on the cutting edge or fund a proven design up to the individual. A shallow 15 inch ultra long throw is an idea that I have been kicking around for quite a while. I also have options to produce parts sourced abroad and assembled here if that is of importance. I take pride in being able to offer some of my stuff to people in a made in Canada or made in the USA label on them. The truth is I work with the largest loudspeaker forging company on earth, and I know who they make parts for. It's easier to say who they don't make parts for actually. Almost no one does their own heavy forging independently any longer. How much are we talking about? Well in small runs $13 to $15K for tweeters in a 250pc run. Woofers can be done close to the same amount for a 100 pc run. Those are numbers for the product to be landed here in North America. Not FOB China. So looking for an investor. Not massive amounts of money just someone that wants a decent return over about 12 months design build cycle. If a person is serious about giving this a shot drop me an email and we can talk. I have had a few discussions on the warranty part of the store. The impression is that there is none. That could not be farther from the truth. Think about this. Selling to DIY clients is labour intensive. On the average I spend at least an hour with each person answering questions and preparing responses when I have to give a more in depth answer. ( Usually great questions and appreciated.) One in three actually purchase products. So why do I state that these are high performance drivers and if you smoke them your on your own? Pretty simple actually. The level of Quality control that goes into the fabrication of my drivers is unprecedented. Even the famed Scandinavian driver houses are not ahead of the test regime that my drivers go through. And actually I know of none that are even equal to my test protocol. Every cone is weighed. Spider compliance is tested throughout the run. All hard parts are tested for dimensional accuracy. Most of my baskets are custom. I take off the shelf baskets, work with an awesome factory that is willing to custom machine them to allow for greater utility in the design work that I am looking to accomplish. It's how for instance I can get the excursion I do out of some of the baskets that I use. They are not stock baskets! A great case in point is the shallow woofer that I am working on. The assembly methods are fool proof in the centering of the magnet on the motor and the height of the voice coil in the gap. Once set, they are no longer able to be altered. That means that if they pass the testing, they meet or exceed the design targets. None of the famous build houses for instance test the motor flux density by an actual probing of the motor at four points on the clock. ( 12, 3, 6, 9) That is every single motor on every single production run. https://www.youtube.com/watch?v=OwkjpKO0V80 Every single driver I make available is tested in this manner. The drivers that are low in flux density are either recharged or scrapped. Every single driver is frequency response tested, and T/S parameter tested. They again either pass or fail. If they fail they are not shipped to me. And I do perform random samplings of testing just to make sure my build house is performing these tests. I have been there and verified the accuracy of the testing methods and that their calibration is indeed correct. So in effect I buy no duds. I sell no defective or suspect articles. The reasons for any failure are not related to the manufacturing processes. Yes this costs money. In the realm of 8 to 10 dollars more on woofer compared to competitive build houses. But the competition doesn't do the same level of testing either. So rather than work in the good old dragnet fashion of selling everything that comes off the production line. And offer a warranty because there is no other way to protect yourself against failures. I work the other way around. I sell products that are guaranteed to perform as they are specified. And I use no fancy wording to exclude their warranty. I state it up front. I have done my job to the limits of what I know and understand to push the limits of quality and performance. I have done everything conceivable to provide a quality product. So if you smoke em, well that's simply not my fault. https://www.youtube.com/channel/UCjhL86Eih-SnTPGByh9RfKw

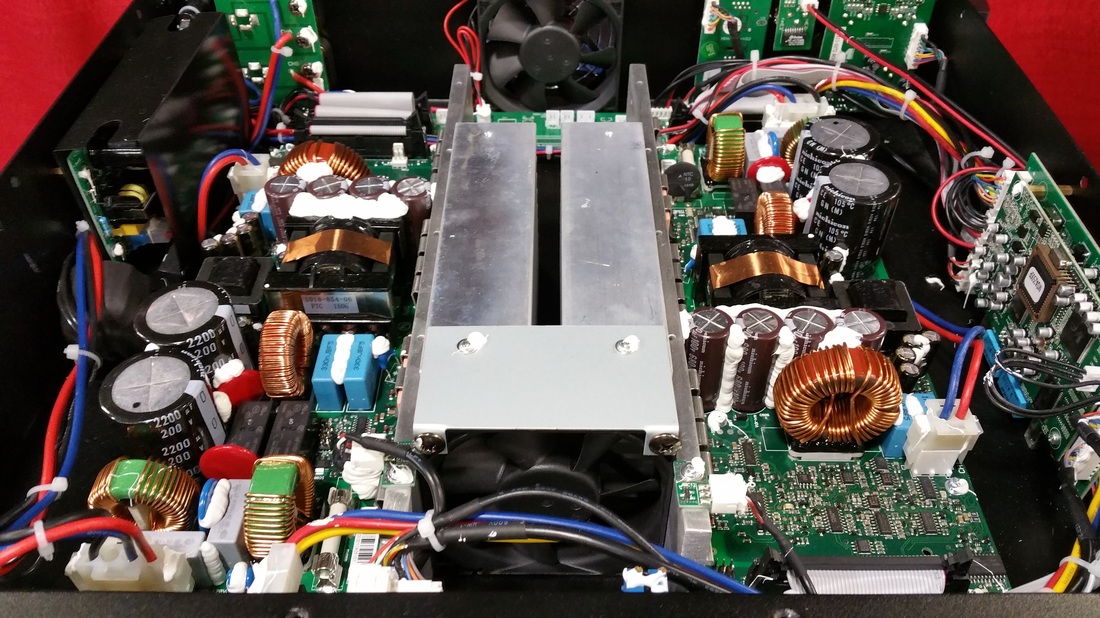

So ever wonder what I'm up to in terms of projects? Take a look at the above link and it will speed you along the internet to my Youtube channel. I put some stuff up there from time to time. If you have any requests about something to video I may be able to help out. The big entrance. And below the equipment rack. The booth in all it's glory. Interior of a 5 Kw amplifier. 2.5 Kw / channel.

I will be at the Marani Amplifier booth in Hall E. Kravchenko Audio is proud to be the Canadian distributor of Marani Audio products. This NAMM event is the kick off for some very high quality pro audio products.

Marani specialises in rack mount and plate amplifiers that are state of the art. Built for real life use in Pro-sound applications. Quality sound and quality build. Feel free to contact us about any inquiry. Well I have heat on demand. And a shop that gets no colder than 15 degrees Celsius. 59 for the Americanos! Or for me a few years back way back, when I had hair!

This lovely innovation allows me to make measurements and prototype work as well as the odd custom job where and when I please. I have a rather large job almost done and another one that I am really looking forward to seeing completed. The HTH the Home Theater Horn. I had to call it something. It is a full front loaded horn two way system that is a dual concentric. I have had this promised to a client that has the patience of Job. He will get a great product. Happy to say that I have a home theater to install in the near future. One that is again fully horn loaded. Horns can do things that pretty much nothing else can match. And in the hands of a capable designer are perfectly good at creating a very realistic soundstage. What they can do in the low end is unearthly. Seriously it is difficult to explain unless you have heard a real properly designed horn subwoofer. It has a completely effortless sound and dynamics that no amount of watts can match from a conventional subwoofer driver. You have read that there is nor replacement for displacement? Well take it from this guy that there is no replacement for efficiency and dynamic range. Displacement can take the back seat in this arguement. Efficiency can really kick butt! Well I succumbed to the pressure.

After many requests to supply more drivers I start the little offerings with the tweeter. I will keep a few drivers available in 3 installments each year at this point. I have a 100 tweeters on their way to me, and I have three bids out for tweeter mounts. All the mount bids are domestic. They should be available in a month or so. The pricing is a bit aggressive. Reasoning is simple. If you want them the price will be lowest at the beginning of each 4 month cycle. Each month into the cycle the price will go up by $20. Keeps things simple. So what does a guy do when it gets cold and he wants to work in a shop with no heat? Yes the Venerable Fisher Momma Bear is being driven out to the pasture. That's my Dad in the drivers seat. That crazy wood stove weighs in at 400 lbs or about 180 kilos. Quite an interesting lift. One more job for the tractor. Good tractor..... And the big empty is now been officially occupied by something a little more modern. I spent the past two days getting to this point. Electrical is done. Oil line is installed and so is the chimney.

Just need a little thing called a thermostat. And heat on demand. Oh the modern conveniences. And this will accommodate an interesting thing called work when I need to. No matter what temperature old man winter throws in my direction. Onward and upward. Now to some more important and interesting projects. Sometimes getting jobs done takes me way, way to long. This is a poster child for a job falling off of the rails. And it is finally back on the rails. The litany of road blocks is cleared away and I have successfully glued up horn profile number one of 12. The pump worked out perfectly, and the shape is just as expected. I should be able to make up about three per day. So I might have the beginnings of the first horn by Friday. Pics and videos below. Well let's say it has been quite a humbling experience. This idea of becoming a sales point for drivers has been only 10 to 12 times more work than I originally thought!

But as the ripples and kinks get smoothed out I am learning many new things. And happily with some of the massive delays I have found some domestic suppliers for parts that are causing me consternation. Onward and upward. I have put up three videos that I made a while ago on the tweeter groupbuy page. They describe crossover effects, dome directivity versus frequency. And the effects of a shallow mount on the tweeters dispersion pattern.

Take a look at this site, and run the test.

You might be rather surprised as to the state of your hearing. This link takes you to a website that allows a degree of hearing testing that is quite rare. What you can perceive from this test is what your hearing is like over a very broad range. Much greater than that given in standard audiology testing. http://newt.phys.unsw.edu.au/jw/hearing.html Yes, it's the simple things i life that really matter. Heat, being one that really helps in working on things in comport.

A friend of mine donated a beautiful furnace to me today. It's almost new. So I'm setting it up net week, and I can finally work at will on almost a months worth of prototypes and custom builds. At long last! Well this has proved to be a very cold winter. In fact right now our daily high temperatures are lower than the normal low night time temperatures. This makes for a difficult situation for my side projects. I spend more time cutting wood and attempting to keep my shop warm, than I do working on projects!

Yes it is well insulated. It's just been that cold. So what can a guy do? Install a furnace. It's not like I have much of a choice. I have two really cool projects I am itching to finish that will only be possible if I have a degree of climate control. Wood glue does not like temperatures much below 12 degrees Celsius. And most mornings, no matter how full I load up my Momma Bear woodstove I'm fortunate to have 4 to 5 degrees on my thermometer. Not good for gluing up bent laminations and beautiful curved horns. So there will be some heat a coming shortly. And much work to catch up on. This years flu season has been nasty. And I got it bad. Just getting up to speed after almost a month of sporadic activity. You know the feeling of I'm not staying in bed any longer... So some updates on the custom Work page. And some tweaks by Steve. Thanks Steve. So two projects are in the shop and in different stages of started. Keeping warm enough to work on projects is a bit of an interesting chore these days. I get the wood temperatures up to about 16 degrees Celsius (about 61 F) by 1:00PM usually. Does not make for a productive day. I heat my workshop with wood in a wood fired stove. So here we are moving firewood. My papa on the tractor. Beats carrying it by hand!

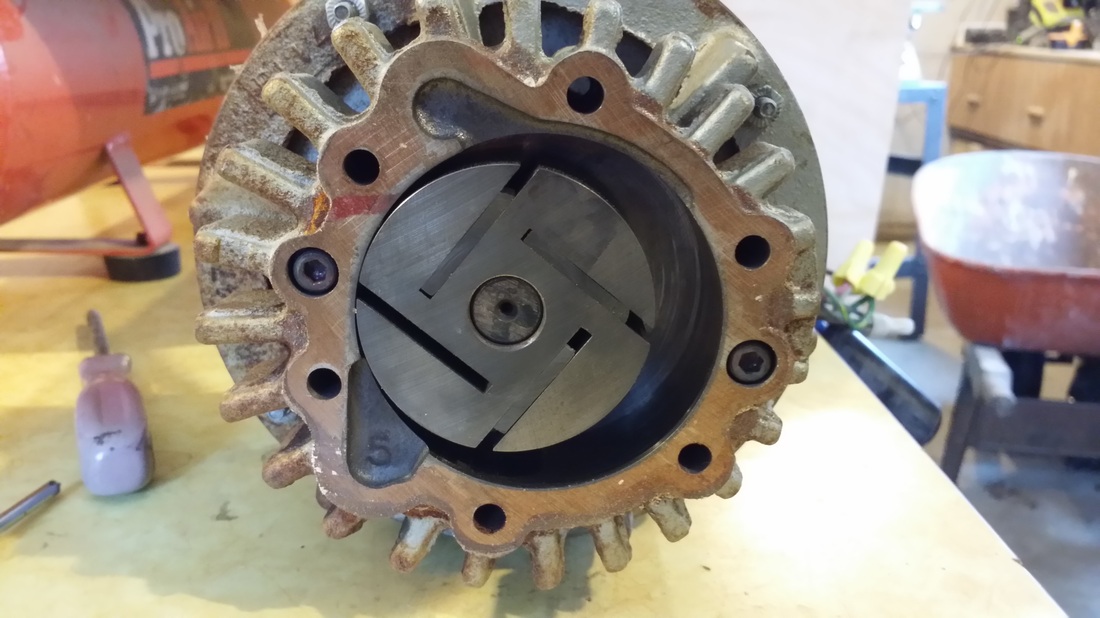

This is a picture of a rotary vane vacuum pump. Notice there are no rotary vanes! They are normally in the slots that are totally or partially filled with black stuff. The black stuff is supposed to be a firm rubber compound. A few days of work, and then no more vacuum. Can't really complain, the pump is almost 30 years old. It has paid it's dues to my workshop. The replacement and the defective little monster are below. As a little bit of bigger is better, I now have a real monster of a vacuum pump. So a trade up in a round about manner.

This little monster enables some custom work to finally get moving towards completion. And I get to get my hands dirty a bit and spend less time in front of a computer for a while. Pics as to what this little setup does will follow. Well there have been some site changes made. Some new pics and videos are up.

You get another new video, some new 15 inch pics. In the custom page there is quite a few pictures of a CBT that I started a while back. And some general housekeeping by Steve to keep me on my toes. Been busy the past few weeks, and fighting off colds like everyone else around here. New and interesting pics will be up shortly. Can't put to much all at once! Well the fun and games of pushing the cabinetmaking envelop. My vacuum press is acting up and I have to do a partial rebuild. I'll post some pictures tomorrow.

So what's a vacuum press you may ask? It's composed of two parts. A bag, and a pump. The object you want pressed is enclosed into a bag and you draw a vacuum on the bag causing the atmospheric pressure to press onto the object within the bag. It has application pressing things that are flat like veneered panels. And applications that are curved. What I'm working on is definitely curved. A few types of horns that are quite curvy. One is a set of three Le Cleach midbass horns designed for awesome reproduction. I'll post pics of them soon. |

AuthorMark's Ramblings, show and tell. And other sundries. Archives

December 2019

Categories |

|

Service/Contact Hours

Monday: 9AM–5PM Tuesday: 9AM–5PM Wednesday:9AM–5PM Thursday: 9AM–5PM Friday :9AM–5PM Saturday: Closed Sunday: Closed |

RSS Feed

RSS Feed